Stonehenge isn’t the only showcase of great engineering in the English county of Wiltshire. There’s also Dyson, which for more than 30 years has been working magic with small motors rather than 25-ton stone slabs, and dreaming up designs made for earthly, rather than spiritual, pursuits.

Although the 700-acre Dyson technology campus doesn’t attract tourists, or modern-day Druids celebrating the solstice, the two sites still have a lot in common. They’re testament to human ingenuity, persistence, hard work and a place where dreams were, and are, made manifest.

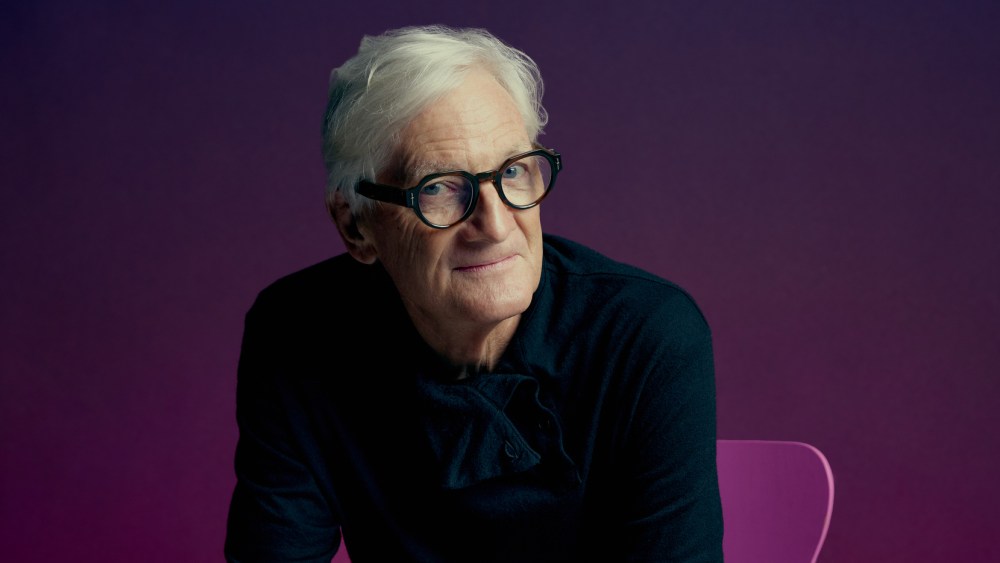

Dyson’s founder James Dyson is a serial inventor, and one of Britain’s few industrialists who can speak fluently about art and science in the same breath.

Related Articles

As a schoolboy he was passionate about Latin, Greek and ancient history, and later stretched his brain in new directions, studying furniture, interior design and engineering at London’s Royal College of Art, alma mater of talents including David Hockney, Tracey Emin, Ridley Scott and Zandra Rhodes.

He made his name in the ’90s with the revolutionary DC01 vacuum cleaner, which used cyclone technology to collect dust and dirt without the need for a bag. Since then, he’s launched myriad, life-enhancing machines, powered by high-speed Dyson motors, one as small as a Champagne cork.

That small, lightweight motor, the V9, enabled Dyson to enter beauty. Now he’s breaking more ground with the launch of a new, and unexpected, category which he hopes will be as disruptive as his well-known styling tools: hair care.

Dyson’s new Chitosan cream and serum, which launch this month, coat individual strands of hair with a micro-structure inspired by the triangles of a geodesic dome. The formulas promise flexible, all-day hold with movement, shine, and no crunchy texture. They have been developed to work in tandem with Dyson hair tools, but can also be used on their own.

In an exclusive interview at the Wiltshire campus, Dyson described the move into wet products as “natural, but different” for the company.

“Different because it’s a formulation, not a product, but not so different in that we’re understanding the science of something so we can improve it — and make breakthroughs,” said Dyson in his deep, smooth tones.

No Satisfaction

Hair care is just the latest chapter in Dyson’s long tale of disruption. While that original DC01 may have made him famous, and fabulously wealthy — Dyson and his family have a net worth of 2.2 billion pounds, according to The Sunday Times of London 2024 Rich List — it wasn’t his first invention.

In the 1970s, Dyson designed the Ballbarrow, a wheelbarrow poised on a single, lightweight rollerball. The ball technology was later used for innovative boat-launching frames that could work on land and sea.

While still a student at Royal College, Dyson helped to invent the Sea Truck, a flat-hulled, high-speed boat that’s able to carry heavy cargo and land without the need for a harbor or a jetty. The Sea Truck is now proudly on display at the Dyson campus, which is a showcase of art and science, reflecting his background and passions.

A fully-restored English Electric Lightning XM173 warplane is suspended from the ceiling of the staff canteen, while a series of Antony Gormley lifesize human sculptures mingle with the actual humans dashing from building to building on the sprawling green campus.

Over the decades, Dyson, 77, has never stopped stretching his brain. He and his team have refined the original vacuum cleaner, and added to the oeuvre with lightweight, streamlined machines such as air purifiers, headphones and hair tools, all of which are becoming increasingly intuitive and adaptive to consumers’ needs.

His ethos is, and has always been, to iterate, re-iterate and improve. His family motto, translated from Latin, is “Never give up trying.”

“The thing we hate is being satisfied, so we’re always dissatisfied — it’s a feature of creative engineers. They always want to go on fiddling, or completely changing, and doing things in a different way. We reinvent ourselves, and kill the old product,” said Dyson.

The entrepreneur took the same approach to hair, wondering why anyone would want to balance a heavy hairdryer in their hand for such a length of time. “It just seemed not very efficient,” said Dyson who, like an enthusiastic physics teacher, arrived at the interview equipped with a series of hairdryer motors of various sizes.

The Dyson V9 is the smallest by far and runs at 110,000 revolutions per minute. He compares it to a larger, more conventional one which notches just 50,000 rpm. Dyson also came up with the idea of fitting his small motor into the hairdryer handle, making it easier to manipulate.

“So it all started with motors, which doesn’t sound like ‘beauty’ — or very romantic,” said Dyson, whose first hair dryer, the Supersonic, launched in 2016. The Supersonic’s research and development took 50 months, 103 engineers and a steely determination on the part of Dyson and his team to know absolutely everything about hair.

“We started buying human hair tresses, trying to understand what caused damage, what was bad for the skull, what makes it strong, and how to style it,” he said. “The more we got into it, the more excited we got, and the more we felt we had technology — and could develop the technology — for products that were better for the hair and could give it a better style with a smaller, and lighter” device.

Since then, he’s been wearing his snow white hair long-ish so that he can personally test all of the products under development. It’s a little too long now, he admitted, so he’ll be getting it cut later in the week by Larry King, Dyson’s global hair ambassador whose London salon counts Adele, Tom Holland, and Jack Whitehall as clients.

Dyson said that, in some ways, the process of developing hair tools has been similar to developing other machines. In other ways it could not be more different. “Vacuum cleaners are very utilitarian, although some people are passionate about them,” he said with a smile. “Whereas when we launched the hairdryer, people got really passionate about it, and absolutely understood everything we were trying to do. There’s a very personal, direct link with the customer.”

That first foray into hair care sparked a deeper interest with the category — and a key realization. Although his engineers have come up with a series of new or improved dryers and stylers in the eight years since the Supersonic debuted, Dyson and the team realized they needed formulations to go with the tools.

Dyson believes that many of his customers have a “huge interest in the science, and the reason ‘why.’ If you can show why something occurs, if you can show the reason and the science behind something, then people are very interested,” he said.

That’s why, on Aug. 15, the company will launch a hair care line called Chitosan, with formulations that can be used on wet and dry hair. It will debut with pre-style cream, for priming, and a post-style serum, for defining. The formulation is the fruit of Dyson’s trademarked Triodetic technology, and the main ingredient is chitosan, a copolymer derived from the gills of oyster mushrooms.

Chitosan is a sugar that’s also derived from the hard bits of shellfish. Sustainable textile manufacturers are currently working with it, and it’s also used in drug manufacturing to regulate the human body’s absorption of fat and cholesterol. It also helps with blood clotting and wound healing.

The chitosan that Dyson is using is found in the cell walls of mushrooms, and helps to give the fungi their shape. It allows the new products to have a flexible hold on the hair.

The pre-style cream is meant to be used on a damp, towel-dried head and is formulated for all hair types. Customers can choose from two formulations, “straight to wavy” and “curly to coily.” They can then opt for a light conditioning formula, or a rich one. The serum, which contains hyaluronic acid, is for all hair types. It’s meant to reduce frizz by up to 50 percent, and add shine.

Dyson has also engineered smart packaging. The full-size bottles, which cost $66 (and $59 for the refill), deliver precision dosing of the highly concentrated formula, exactly 0.22 ml, with each pump. The smart dosing is meant to minimize waste, and allow customers to decide exactly how much their hair needs. The full-size packages, all of which have magnetized caps, are also refillable, and the refill cartridges are recyclable.

Although the cream and serum can be used on their own, they were designed specifically to work with the new Airwrap i.d., the brand’s first connected beauty device. Dyson described it as an intuitive, aerodynamic multistyler and dryer with Bluetooth technology that allows users to program ideal temperatures, timings and techniques to achieve the styles they want via the MyDyson app. It also keeps the temperature below 150 degrees Celsius, the point where hair starts to become damaged, and manipulates air flow so that hair doesn’t get too hot or overworked.

It has 19 attachments, including a diffuser that disperses airflow in two different ways, and a conical, multidirectional barrel for more defined curls. The airflow in the device relies on the Coandă effect, similar to when air arches closely over the wing of a fast-flying airplane, creating lift.

The airflow in the Dyson barrel attracts, and self-wraps, the hair, while the diffuser and the blade concentrator attachments also rely on Coandă aerodynamics to shape the hair without overheating it.

A new MyDyson app has been created to support the tools and the formulations. Users can input their hair type and length, skill level and desired look. The app, which syncs with the hardware, recommends an ideal curling or styling routine. Timers let the user know the ideal moment to release the device and move onto the next section of hair.

The app can also be used to check the status of the tool’s filter, while an LED light on the machine flashes when it’s time to clean or replace it. It can also connect to an NFC chip embedded in the cap of the Chitosan cream and serum bottles, driving customers to a Dyson page where they can reorder products, learn about hair care routines, and read about ingredients.

The Dyson DNA at Work

While Dyson’s cordless vacuum cleaners may be slim beauties with LCD screens, sensors and color schemes featuring shades like “Prussian Blue” and “Rich Copper,” the company is still relatively new to the beauty business, and called in outside expertise for the launch of the formulations.

In 2022, the company announced a 500-million-pound commitment to the beauty division, earmarked for the research and development of 20 new products across a four-year period. That same year Dyson hired Estée Lauder Cos. veteran Kathleen Pierce as global president of Dyson Beauty, who has since assembled a team of sector experts with hair, styling and formulation expertise. That team is now working alongside Dyson’s engineers, chemists and industrial designers on the Wiltshire campus.

“We’re the least likely beauty company. We’re a bit the underdog in that way, but that’s a space we’re comfortable in,” said Pierce, who was devoted to her Dyson Supersonic long before she joined the company.

She said that Dyson “genuinely looks at spaces and tries to understand where we can be a challenger. The vision is to keep pushing boundaries when we have a point of view, and something to say. We have a core foundation of knowledge that we tap into for each category.”

When it comes to innovation, “the sky’s the limit,” Pierce added.

Pierce said the Dyson team has wholeheartedly embraced beauty R&D, and was undeterred by the prospect of developing creamy formulations rather than household-focused hardware. Although she joined two years ago, chemists and formulators have been working on the Chitosan products for the past five years at some of Dyson’s 300-plus labs across the world.

Over the years, researchers have explored why some types of hair can hold a style and others can’t. They also examined the properties of chitosan and its ability to “build” a long-lasting structure around a single strand of hair, and eliminate the need for hairspray, which one Dyson scientist referred to as “just a posh version of glue.”

They deployed tools and machines to measure hair’s ability to bounce, and looked at what happens when hair moves through an air current. They worked on creating quality curls that don’t wilt after a few hours, and spent their days researching techniques and ingredients to keep frizz at bay.

They took pains to ensure the new, wet formulations didn’t leave any residue on hands or hair, and that they smelled good, too. “Until now, all of our tech has been aimed at removing smell. Now we’re developing fragrance profiles for out products because sensory signals are important,” said a chemist who worked on the launch.

The micro-dosing capability also required great attention. “We didn’t want there to be any waste,” said one engineer. “We found that hair stylists [and the end-consumer] were using far too much product, and that was weighing hair down.”

“We really leaned into dosing because if you think about your optimum hair experience, it comes from repetition. You want that same beautiful result every time,” said Pierce. “But the level of mechanism to create precision dosing is incredibly complex.”

The Chitosan products and the Airwrap i.d. will launch on Aug. 15 in the U.S. and Canada, at Dyson stores, the brand’s website and major beauty retailers including Sephora. The products will roll out internationally during the month of August.

Pierce also sees the launch of Chitosan as a way of bringing new customers on board. The $66 formulations are an entry price point for the brand, where the basic Supersonic costs more than $400.

Asked how big the beauty business could get, Pierce answered in Dyson style.

“How many problems are there to solve? There are categories and spaces and things that makes sense for us, but we won’t be pressured to pull into certain categories [for the sake of it],” she said. “We will only launch things when we have something that’s disruptive and innovative. And we have a robust roadmap.”

Looking Ahead

James Dyson is still brimming with ideas, forging ahead, and aiming to lead by example every day.

He said the scientists, chemists and engineers on staff are yearning to innovate, and he’s pushing them to develop new technology at pace. His ingredients for success are enthusiasm, and a lack of cynicism.

“Often the naïve suggestion is an interesting one, which is why we like working with young people and engineers. They challenge us, and it’s one of the reasons why we have the university,” said Dyson, referring to the Dyson Institute of Engineering and Technology, which combines the academic rigor of a traditional university with hands-on experience at the company’s Wiltshire campus (see sidebar).

Despite a round of layoffs announced earlier this summer (around 1,000 jobs, or one-third of the U.K. workforce, will go due to what the company has described as “fierce” global competition) Dyson said the company will continue to improve its products.

“We see great opportunity and we’ll continue to develop technology and design things that solve problems. It’s just the beginning and there’s a lot of research going on,” he said.

“Because of technology, because of sensors and AI and software, there will be more and more to invent. There will be huge technology improvements and huge ‘sensing’ improvements — things that tell you exactly what’s happening and what you’ve got to do.

“Health products are an obvious example — there are going to be huge advances in that,” he said. “But we still need to know more. There’s a thirst to know why something is happening, and how you can prevent certain things from happening. In the future we’re going to make leaps and bounds that will benefit us all.”